Yuzen Washi Printing

Unleash Your Creativity and Unveil the Beauty in Tradition

- Production of yuzen washi paper in original color designs

-

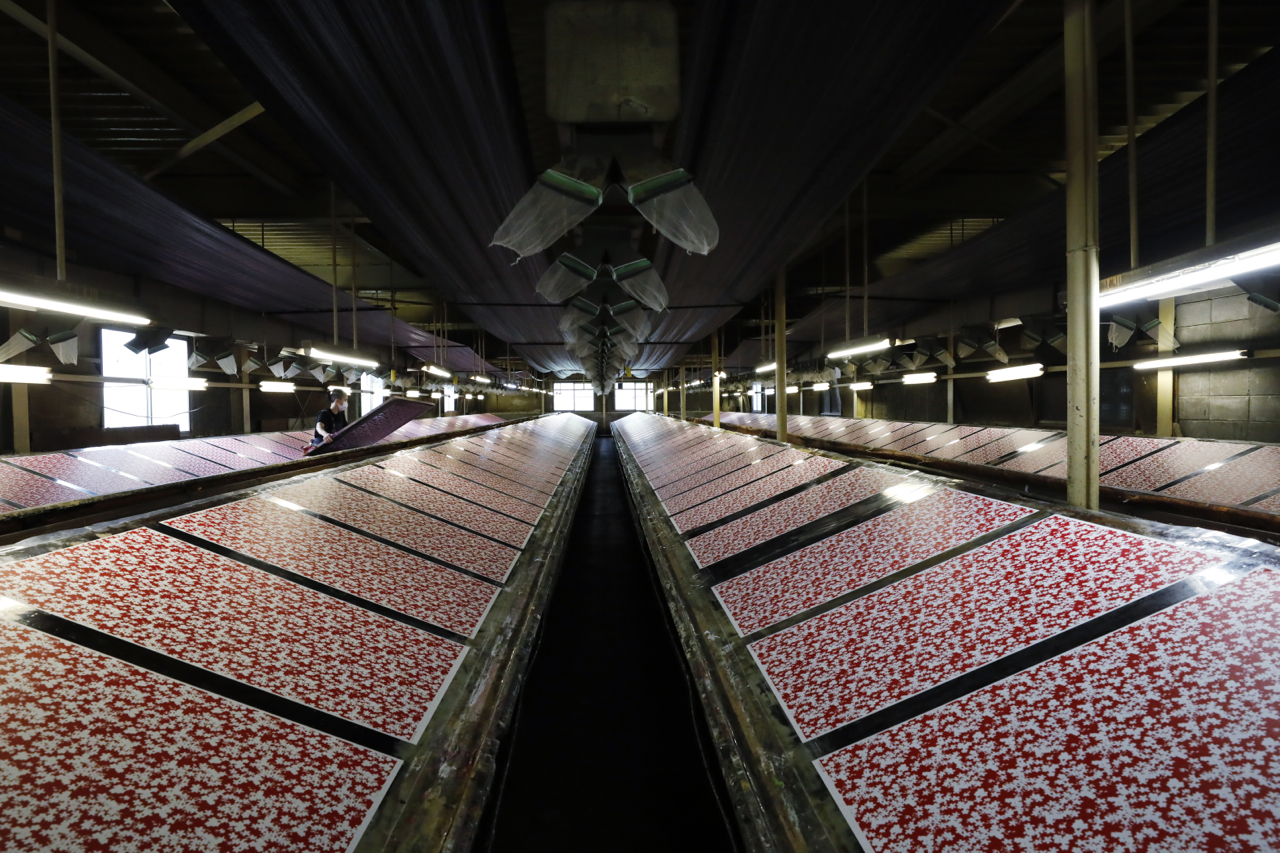

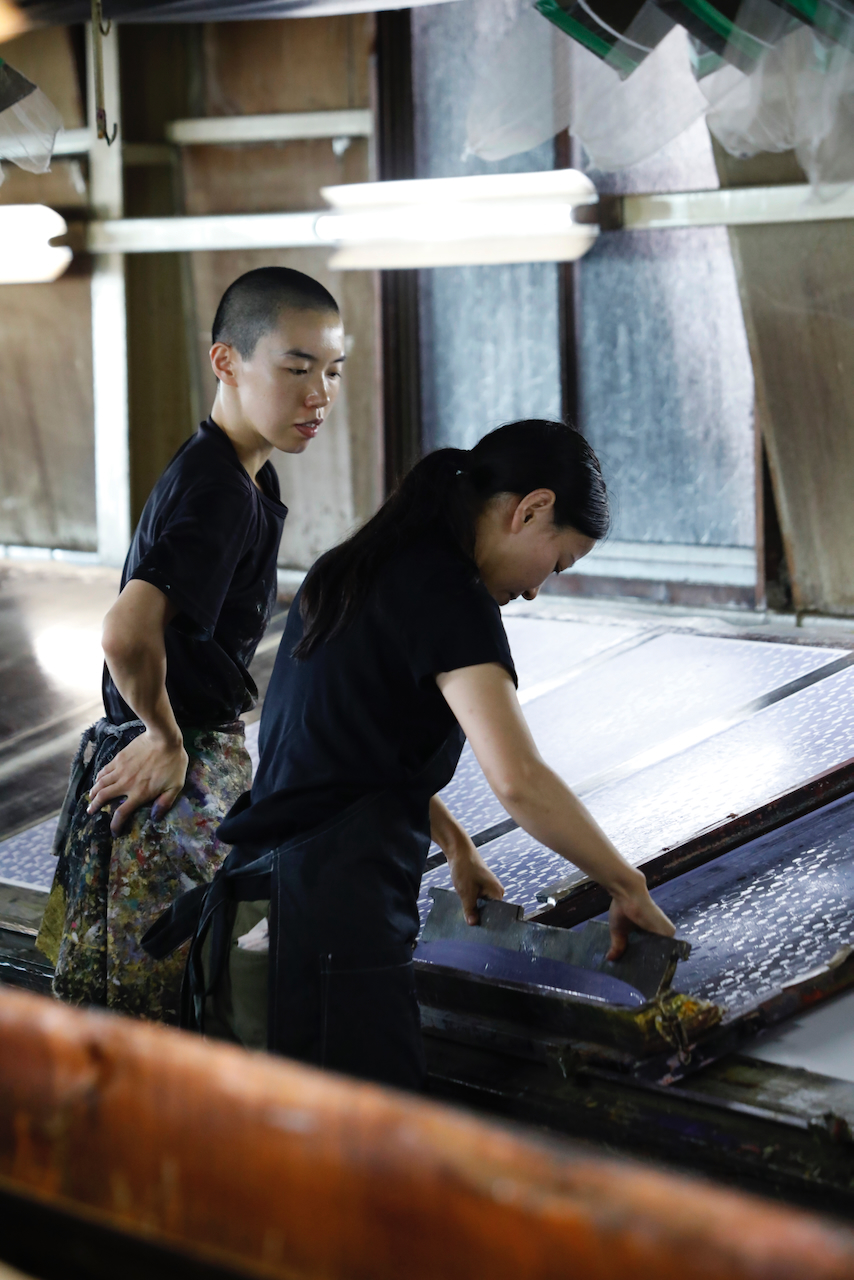

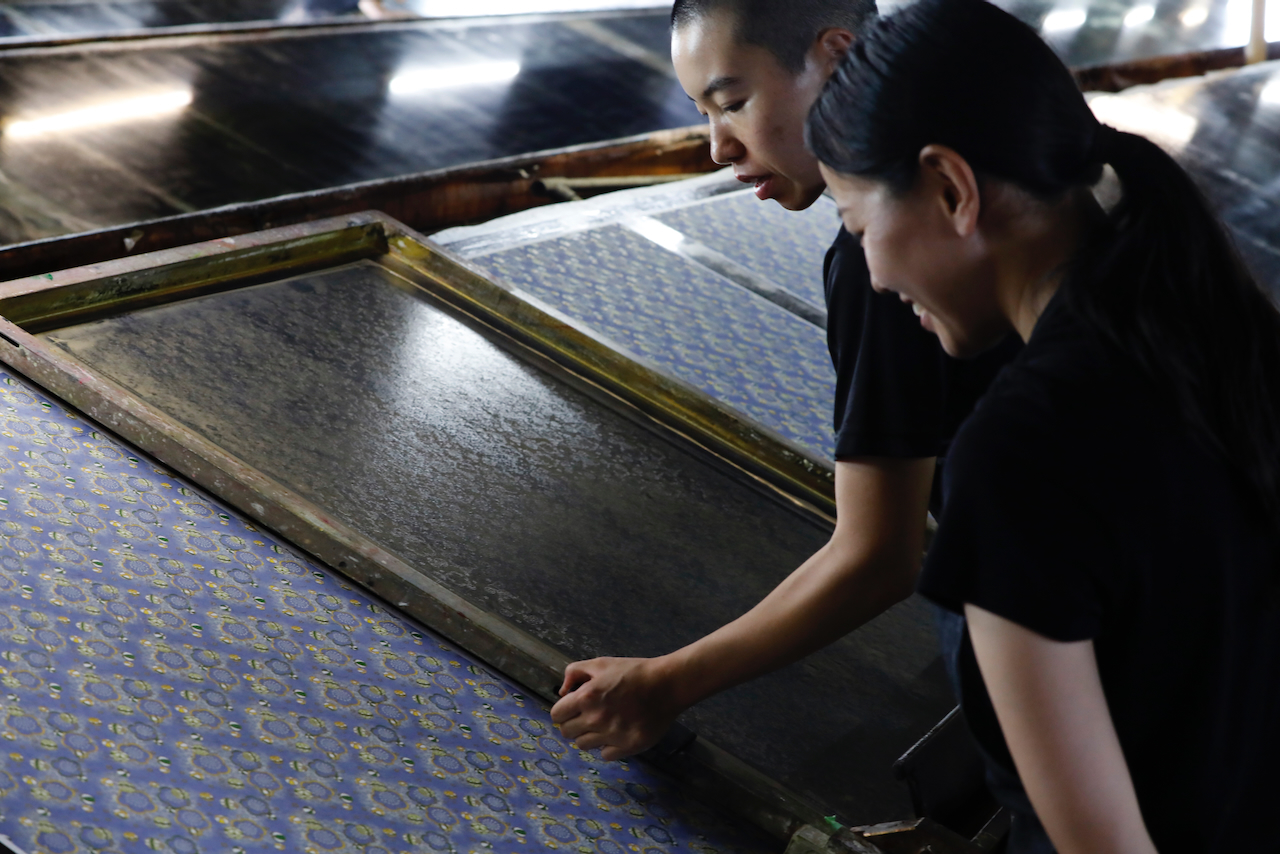

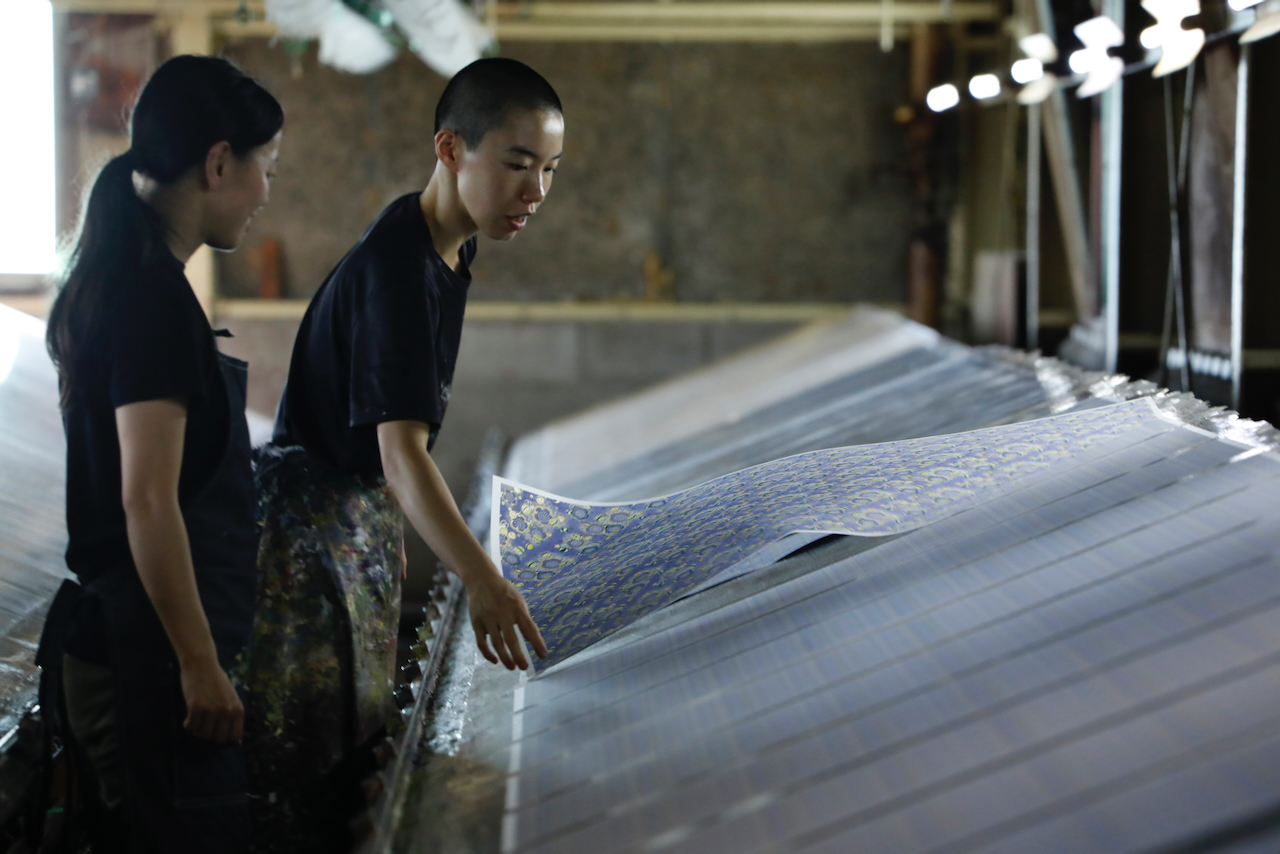

In the workshop of Maruyama Senko, where the printing work is carried out, craftspeople divide up the work, one sheet and one color. The workshop can print approximately 240 sheets at a time, but if, for example, six colors of ink are used to create a single work, the mould is set with ink, printed with a spatula and removed from the mould a total of 1,440 times, so fast and accurate work is required at all times. The process is extremely delicate and results in beautiful, luxurious washi paper.

-

The process of creating the colors to be placed on the washi paper requires even more skill. Even if six colors are used for a single piece, there are hundreds or even thousands of possible color combinations. The colors are mixed while simulating them in the mind. The impression of liquid ink changes as it dries on the paper, and the true finished product is not known until it is printed. Mixing is the most important part of the process, which determines the perfection of the work, and is a difficult job that requires skill and experience.

-

In this experience, craftspeople can mix their own original colors. You can stand in the lane where the craftspeople are actually working, and with their direct guidance, you can experience placing the colors on the washi using a mould. You can make your own original washi in a workshop that is normally not open to the visitors.

- 3D wrapping paper that greatly delights the recipient

-

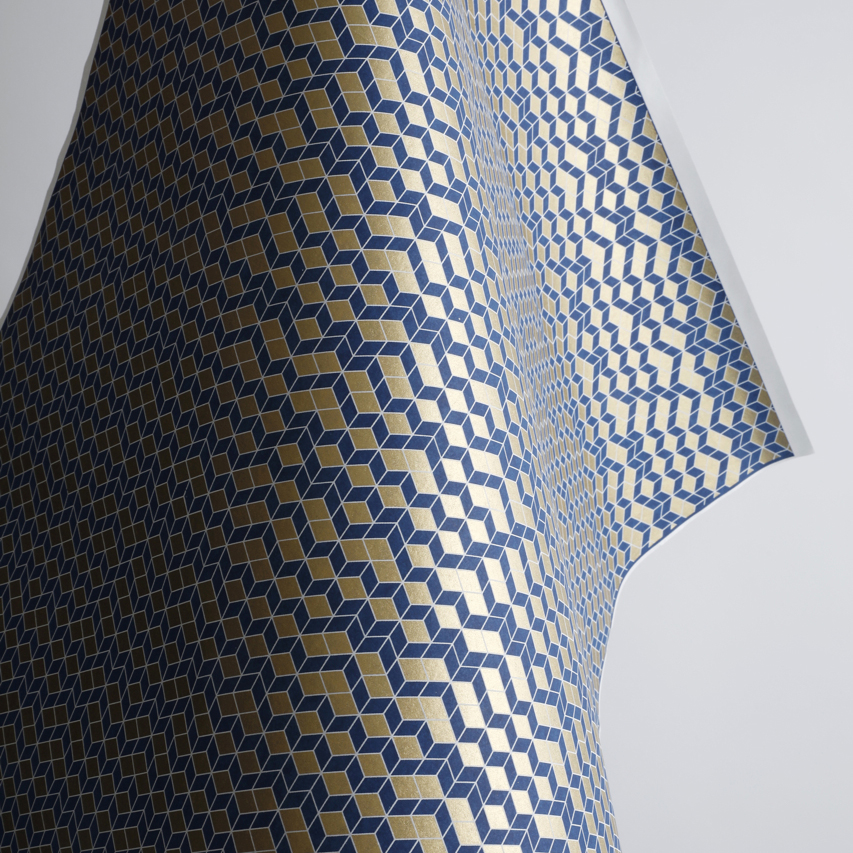

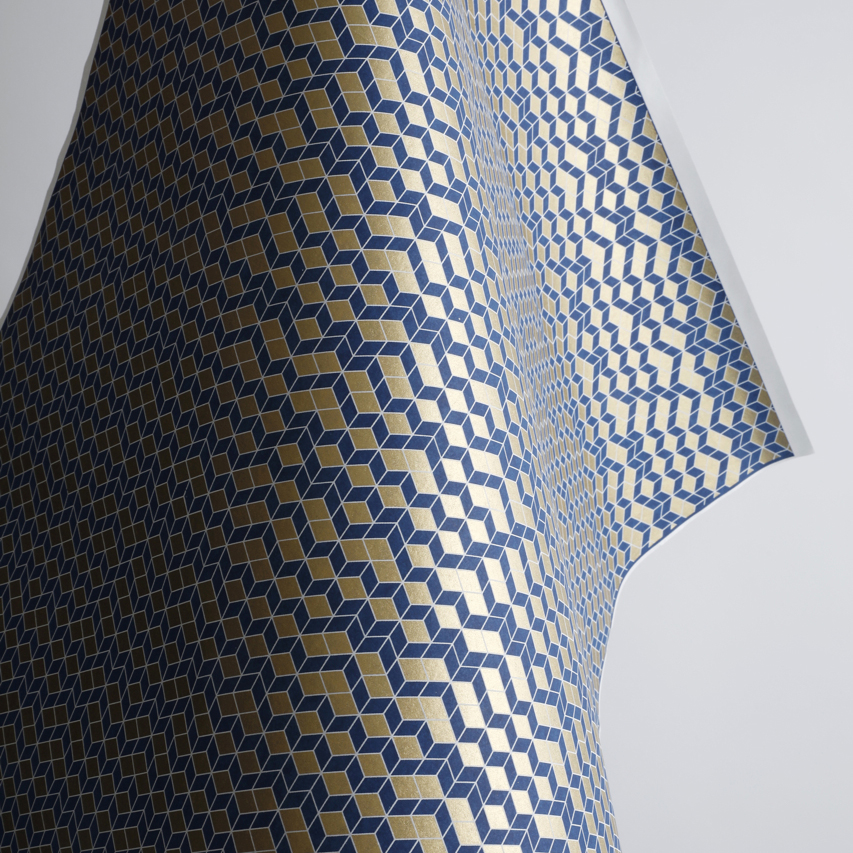

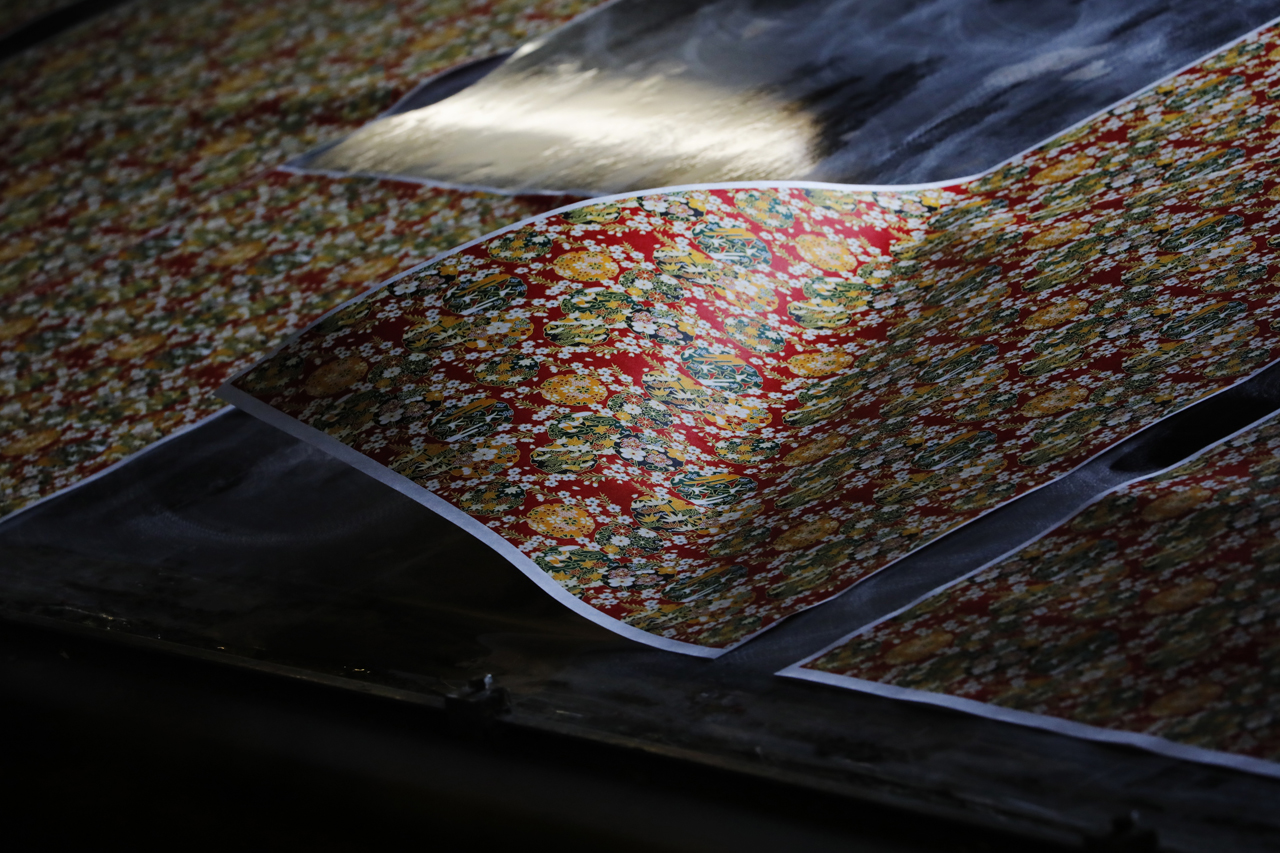

Maruyama Senko's hand-painted yuzen washi is carefully produced one by one with traditional and original yuzen patterns (Japanese patterns) and perfect color matching. The yuzen washi they produce are 3D, powerful, colorful and each piece is extremely beautiful.

In general commercial printing, ink basically soaks into the paper or is fixed very thinly to the surface of the paper, resulting in a flat finish. On the other hand, in Maruyama Senko's process, the ink is fixed thickly on the surface of the paper, giving a 3D finish, which gives a completely different impression from other types of printing. Since all printing is done by hand, each sheet is slightly uneven, which is also a good feature.

This yuzen washi can be processed into a variety of products and has an unlimited range of uses, including not only origami, but also decorations on the surface of drum sets, the cover of Goshuin (a red ink stamp) books, and even the dress of Japanese dolls.

- A powerful textile dyeing workshop with its roots in kimono yuzen

-

Maruyama Senko, which produces Kyo-yuzen washi paper, is located near the Oigawa River (Katsura River), which flows through a mountain basin stretching into Yagi, Nantan City. It is a wonderful location with a typical Japanese landscape of vast rice paddies in front of it and the Saburogatake mountain range beyond.

Maruyama Senko is a workshop that has been offering Kyo-yuzen, which is said to have been invented by Miyazaki Yuzenzai in the Genroku era (1688-1704), in the form of Kyo-yuzen Washi paper for about 30 years. Originally, Kyo-yuzen was dyed on fabric, but the president, Mr Maruyama, switched from fabric to washi using his skills, produced original yuzen patterns and started selling them as chiyogami and yuzen washi. When you enter the workshop, you will find lanes lined with washi. Yuzen washi is handmade by craftspeople who use moulds and carefully dye the paper one by one to avoid deformation of the pattern.

- They say

-

“Yuzen washi with the color mixing, the handcrafting of each piece using moulds and traditional Japanese patterns is interesting Japansese culture with many possibilities.

We invite you to visit our workshop and get to know our craftspersonship.”

- Dyeing Specialist

- Kazutake Akiyama

- Maruyama Senko has been offering Kyo-yuzen, which is said to have been invented by Miyazaki Yuzenzai in the Genroku era, in the form of Kyo-yuzen washi paper for about 30 years. Originally, Kyo-yuzen was dyed on fabric, but Mr Maruyama, the president of the company, used his skills to switch from fabric to washi to produce original yuzen patterns, which are sold as chiyogami and yuzen washi.

Access

- Nantan (30 mins. train ride & 10 mins. walk from Kyoto Station)

- JR Yagi Station is accessible from Kyoto Station via 30 mins. / 510 JPY train ride