Yakishime Pottery

Unleash the True Essence of Natural Creations

- Try making your own pottery

-

Try making our own pottery guided by the artisan and have our original container completed with the power of nature.

No electricity to fire the kiln. No glaze to cover or color pottery. The ceramics made by the artisan is perfectly done in traditional, natural way called Yakishime.

- An artist preserves the traditional method at her studio in her hometown, Kameoka.

-

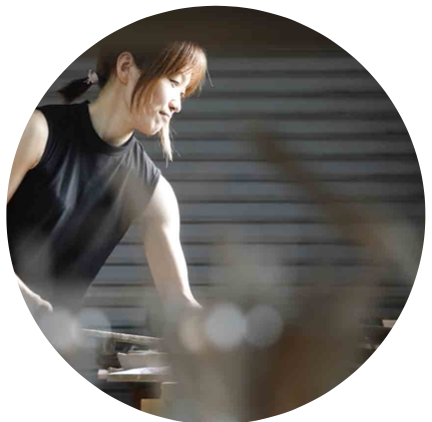

Emu Nakai, a pottery artist, makes pottery preserving the traditional technique of “Yakishime” in her beloved deep forest of Kameoka, with a lush green landscape in Kyoto.

With “Yakishime”, the surface of the pottery is not glazed, but the ash from the wood during the firing process gives the pottery its natural and beautiful colors and patterns.

The pottery is fired entirely with wood, without electricity, and the ash colors the pottery instead of the glaze.

The artist herself cannot predict what colors and patterns will appear on the pieces.

Therefore, the pottery which she makes delights us with the beauty of the different colors and patterns that nature brings to each piece.

“Yakishime”, which does not use glaze, is fired in a wood-fired kiln, so the fire tends to be unstable and there is a risk of distortion or cracking of the fired pottery.

For this reason, pottery made by “Yakishime” is often thicker and larger than normal.

On the other hand, the artist says, "The pottery is made to be used at the table, so it should not be too heavy to hold by hand.”

She is also keen on applying the “Yakishime” technique to achieve the 'thinness' found in Kyoto pottery.

- Kiln firing three days and three nights deep in the forest, gazing the fire

-

The artist builds her own kiln (anagama) over a year, and fires pottery using the traditional firing technique.

During the kiln firing, which takes place three or four times a year, the wood is kept burning for three days and three nights, firing 500-800 pottery pieces at a time. When the fire reaches the target temperature of 1200°C, the fire turns not red but almost transparent white and is very beautiful!

The sun slowly sets and it gets dark. The calls and sounds of insects in summer and the rustling of trees in winter, together with the heat and crackling of the fire, surround the space. Deep in the forest in the silence, hundreds of hours are spent firing pottery while gazing at the fire. Watching the flames, time passes quickly and eventually the pottery, which has been ground extremely thin, is revealed from the kiln in a different and beautiful appearance.

- She says

-

“Since each container is finished with ash flying in the kiln, it is subtly different from each other.

I would like you to enjoy the difference of the color, which gets better and better as you use more.”

- Pottery Craftsperson

- Emu Nakai

- She was born in Kameoka-city, Kyoto Pref.

After graduating from Traditional Arts Super College Of Kyoto, she worked as an apprentice at Tanba Pottery for five years.